Most Popular Products

Showroom

The apparatus and tools required for the wire drawing process are collectively referred to as wire drawing machine equipment. It contains the tools required for drawing wire through a sequence of dies to lower its diameter and enhance its quality, such as lubrication systems and wire drawing dies.

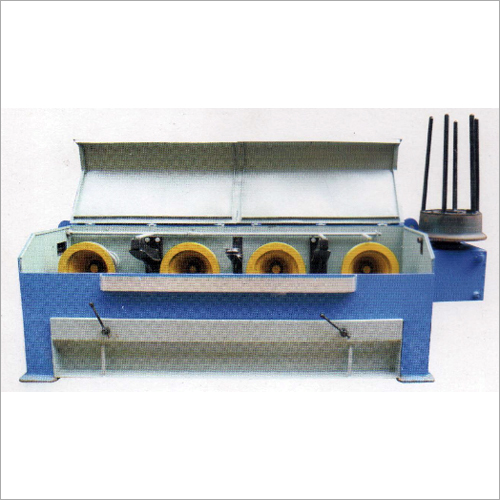

An industrial tool called a rod breakdown machine is used to lower the diameter of wire rods. Thicker wire rods are effectively converted into thinner wires, making them ideal for a variety of uses, including cables and electrical conductors.

In order to obtain the necessary diameter and surface smoothness, wire is pulled through a sequence of progressively smaller dies by mechanical devices known as wire drawing machines. These devices are essential for producing high-quality wires for a variety of applications.

In order to heat-treat wire and increase its ductility and decrease its hardness, a wire annealing machine is utilized. Through this procedure, the wire becomes more flexible and suited for bending and shaping without breaking.

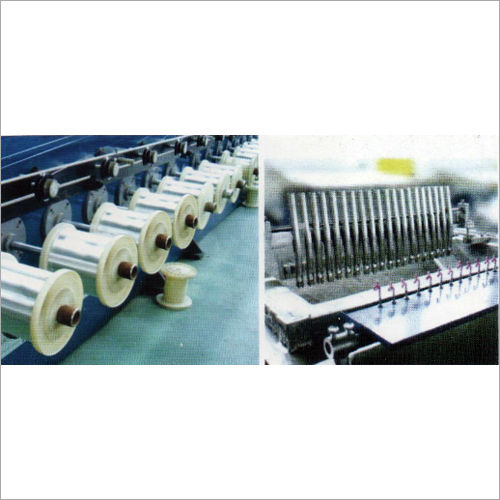

Wires are coated with a protective enamel layer using Wire Enamelling Machines. The wires are appropriate for use in electrical applications because to the insulation's ability to guard against electrical short circuits and corrosion.

To combine several wires into one, bigger conductor, wire bunching machines are used. This procedure is frequently used in the manufacture of cables and improves the wires' electrical conductivity and tensile strength.

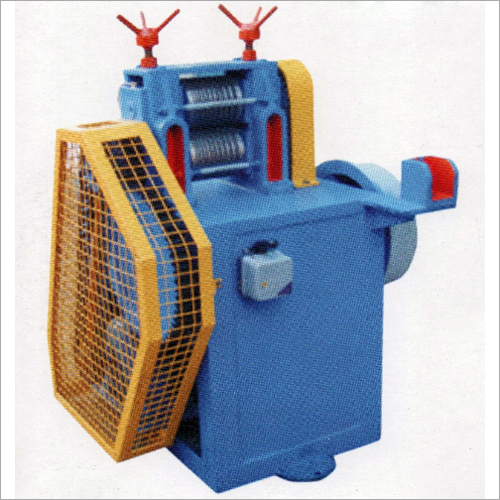

A wire pointing cum threading machine is a multipurpose tool used to thread wires while simultaneously creating pointed ends on them. It gets wires ready for a variety of uses, such welding or fastening.

By adding a thin layer of tin to the surface of wires, wire tinning machines improve the corrosion resistance and solderability of the wires. For cables used in soldering and electronics applications, this is essential.

By melting and fusing the tips of the two wire ends, Butt Welding Machines are used to unite them. Without additional connectors or splices, this technique produces a robust, continuous cable.

|

DC ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |